WELCOME TO HME

High-Precision

Manufacturing &

Engineering

WELCOME TO HME

High-Precision Manufacturing & Engineering

Digital Manufacturing from Early Prototyping to Full-Scale Production

At HME, we deliver precision-engineered manufacturing solutions, faster and smarter. From initial prototype development to final production, our advanced digital manufacturing capabilities ensure accuracy, speed, and quality at every stage.

Trusted Across Global Manufacturing

Trusted Across Global Manufacturing

Our Services

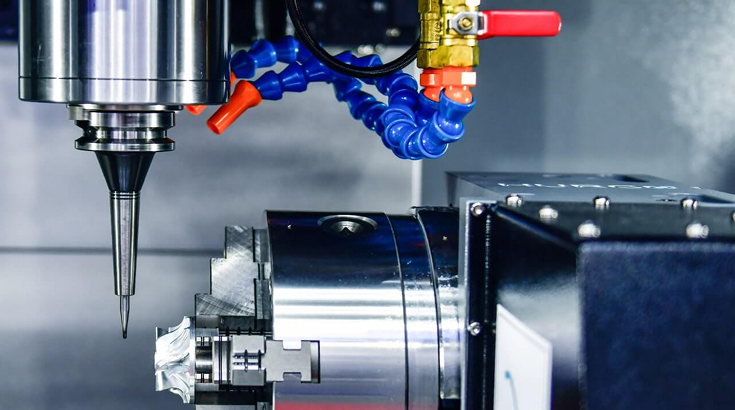

CNC Milling & Multi-Axis Machining

We offer complete CNC milling solutions for precision parts with complex geometries and tight tolerances.

- Multi-Axis Precision – Accurate machining for complex parts and tight tolerances.

- Prototyping to Production – Reliable quality for any project scale.

- Versatile Materials – Expertly machine metals like aluminum, steel, and titanium.

Mill-Turn & Swiss Machining

For components requiring both turning and milling, we offer integrated mill-turn and Swiss machining services that deliver precision and efficiency in a single setup.

- Integrated Machining – Combines milling and turning for faster, more accurate production.

- Tight Tolerance Parts – Ideal for small, complex components requiring high precision.

- Efficient Production – Reduces setup time and ensures consistent quality in every run.

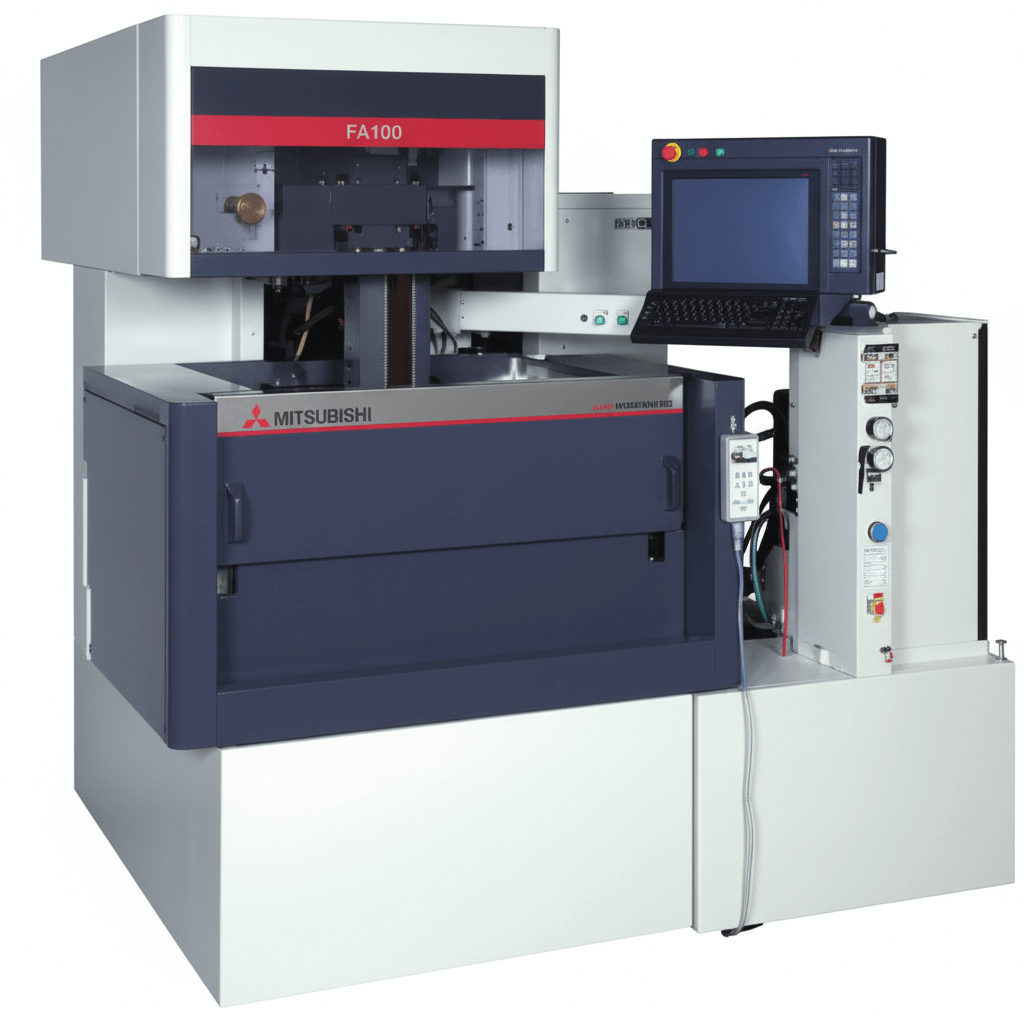

Wire EDM & Tool Room Services

Our EDM and tool room department specializes in high-precision cuts, intricate shapes, and fine detail work for tooling and custom components.

- Precision EDM Cutting – Achieve intricate shapes and fine details with exceptional accuracy.

- Custom Tooling Solutions – Design and manufacture of specialized tools and dies.

- High-Quality Finishing – Delivering smooth edges and flawless surface finishes.

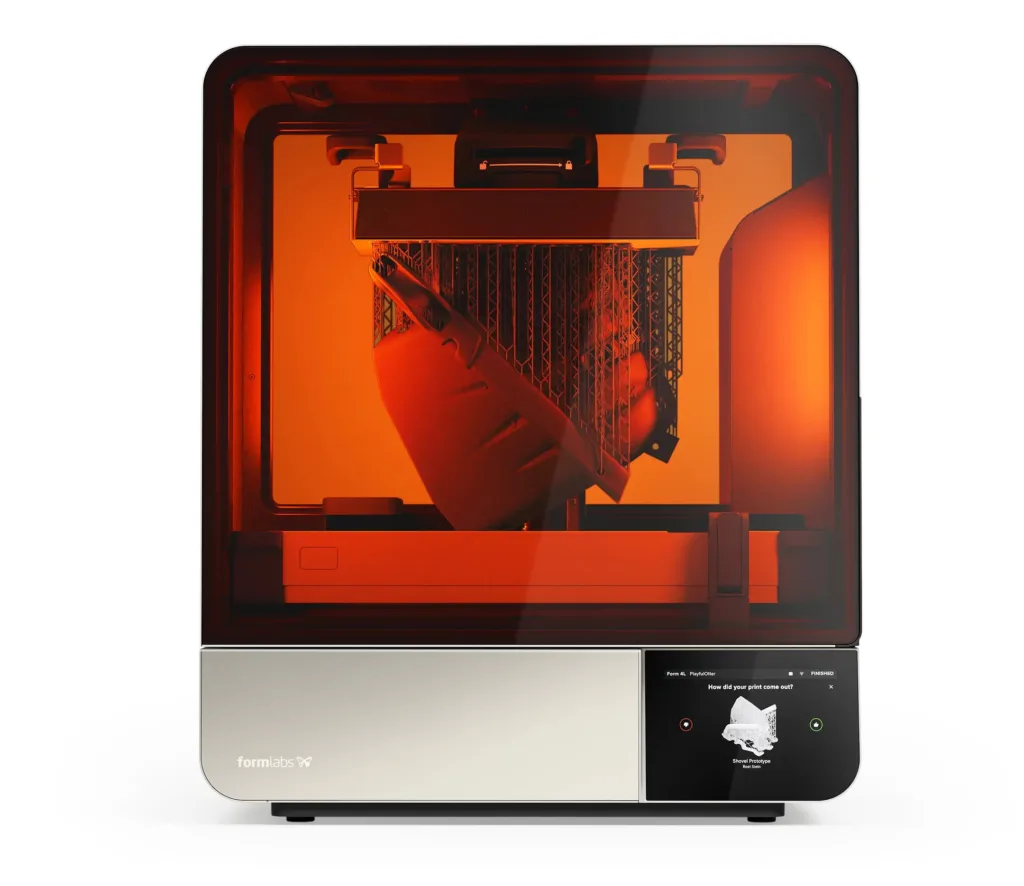

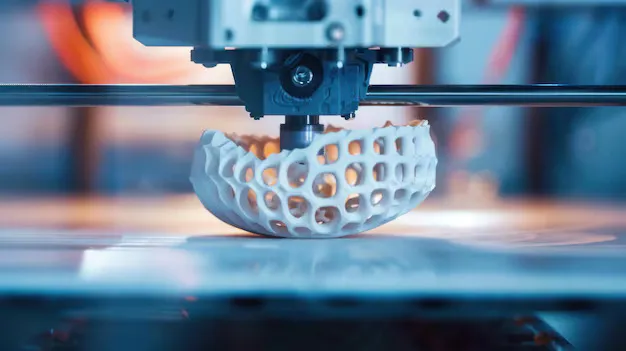

3D Printing & Prototyping

We combine additive and subtractive technologies to accelerate design validation and reduce lead times.

- Large-Format SLA Resin Printing (build volume: 3.9″ × 7.7″ × 13.8″).

- Rapid prototyping for design validation and short-run parts.

- Hybrid workflows combining 3D printing and CNC finishing.

- Post-processing options including sanding, priming, coating, and CNC refinement.

CNC Milling & Multi-Axis Machining

We offer complete CNC milling solutions for precision parts with complex geometries and tight tolerances.

Mill-Turn & Swiss Machining

Wire EDM & Tool Room Services

Our EDM and tool room department specializes in high-precision cuts, intricate shapes, and fine detail work for tooling and custom components.

Quality Inspection System

3D Printing & Prototyping

Engineering Support

Build Like a Pro with HME

We’re your all-in-one partner from concept to production. At HME, we help you accelerate product development and bring your ideas to market faster than ever. When it’s time for full-scale manufacturing, our expert team provides complete project management, optimizing every detail for cost, quality, and production efficiency.

Design and Engineering Support

We provide both automated and personalized manufacturing support to make your project a success. Every quote includes a free design-for-manufacturing analysis to help you improve part performance and production efficiency.

Need additional guidance? Our experienced engineers are always available to discuss your project and offer tailored recommendations that fit your goals, ensuring precision, quality, and reliability at every step.

How We Work

Share Your Design

Upload your 3D model or technical drawings directly through our platform. Our system reviews your files to ensure manufacturability and accuracy before production begins.

Get a Fast Quote

Start Production

Receive Your Parts

Industries

Industrial Equipment

Precision components for heavy machinery and manufacturing systems.

We machine complex, high-tolerance components used in industrial equipment, production machinery, and automated manufacturing systems. Our capabilities support both low-volume custom parts and repeatable production for continuous-duty applications.

Common applications include precision housings, tooling, fixtures, structural components, wear parts, and multi-operation assemblies requiring consistent accuracy and reliability.

Medical

High-precision machining for medical devices and healthcare equipment.

We support medical manufacturing with precision-machined components requiring tight tolerances, clean finishes, and repeatable quality. Our processes are well suited for complex geometries, small components, and multi-operation parts commonly used in medical devices and diagnostic equipment.

Ideal for prototype development, pilot runs, and controlled production volumes.

Aerospace

Complex CNC machining for aerospace and aviation applications.

Our machining capabilities support aerospace supply chains that demand tight tolerances, complex geometries, and process consistency. We produce precision components for structural, mechanical, and support systems, including parts requiring multi-axis machining and secondary operations.

We are well equipped for low-volume, high-complexity aerospace components where accuracy and repeatability are critical.

Automotive

Precision components for automotive and transportation systems.

We machine components for automotive and mobility applications, supporting prototype, pre-production, and production requirements. Our capabilities allow us to efficiently handle complex parts, tight tolerances, and multi-operation workflows common in modern vehicle systems.

Applications include brackets, housings, shafts, precision assemblies, and functional components across multiple vehicle platforms.

Defense & Military

Mission-critical components for defense and government systems.

We manufacture precision components for defense and military applications where reliability, durability, and dimensional accuracy are essential. Our equipment and processes support complex parts used in ground systems, support equipment, and specialized assemblies.

Manufacturing is performed with strict attention to consistency, traceability, and quality control expectations typical of defense supply chains.

Robotics & Automation

Precision machining for advanced automation and robotic systems.

We support robotics and automation manufacturers with high-accuracy components used in motion systems, frames, end-effectors, and mechanical assemblies. Our machining capabilities are well suited for multi-axis geometries, tight tolerances, and repeatable production.

This makes us an ideal partner for both early-stage development and scalable automation platforms.

Resources

Choosing the Right Material for Your Manufacturing Project

Selecting the correct material can make or break your product’s success. Each metal—whether aluminum, stainless steel, or carbon steel—has unique strengths and applications. At Hot-Metal

Why Early Prototyping Saves Time and Money in Product Development

Prototyping isn’t just the first step—it’s the most important one. By creating a precise prototype early, you can identify design flaws, test functionality, and make

How Digital Technology is Changing Production

The manufacturing world is evolving rapidly with the rise of digital tools and automation. At Hot-Metal Equipment, we use advanced digital manufacturing techniques to reduce

End-to-End Digital Manufacturing Solutions

Prototype Development

Low-Volume Production

Complete Manufacturing